In the sprawling industrial zones near every major port and refinery, vast tank farms rise from the

landscape—circular steel vessels sometimes exceeding a million barrels each, holding crude oil and refined products

in the delicate balance between production and consumption. These storage terminals, often overlooked in discussions

of energy markets, wield enormous influence over fuel prices. When storage fills up, as dramatically occurred in

spring 2020, even valuable oil becomes worthless because there’s nowhere to put it. When storage empties during

supply disruptions, prices spike as refineries scramble to secure crude. Understanding how crude oil storage

terminals operate, who owns them, and how their inventory levels affect prices reveals a crucial but often invisible

mechanism connecting global oil markets to the prices consumers pay at the pump.

The Role of Oil Storage

Oil storage serves as a buffer between variable production and variable consumption. Wells produce at relatively

steady rates; refineries run at consistent utilization rates; but demand fluctuates with seasons, weather, and

economic conditions. Storage absorbs these mismatches, ensuring crude is available when refineries need it and

providing somewhere to put oil when refineries can’t process it immediately.

Without storage, the oil industry couldn’t function. Production couldn’t proceed if excess had nowhere to go.

Refineries couldn’t weather supply disruptions if no reserves existed to draw upon. The entire supply chain depends

on strategically located storage capacity.

Strategic vs. Commercial Storage

Two categories of oil storage serve different purposes. Commercial storage, owned by terminal operators, refiners,

and trading companies, supports market operations. The Strategic Petroleum Reserve (SPR), owned by the U.S.

government, provides emergency supplies for national security purposes.

Commercial storage responds to market signals—operators build more when storage is profitable, less when it isn’t.

Strategic reserves respond to policy decisions about energy security regardless of market conditions.

Major Storage Locations

Storage terminals concentrate near production areas, refining centers, and import/export facilities. The Gulf Coast,

processing most U.S. refining capacity and importing/exporting significant volumes, hosts the largest storage

concentration.

Cushing, Oklahoma maintains unique importance as the delivery point for WTI futures contracts. Its roughly 90

million barrels of storage capacity—the largest concentration in America—makes Cushing inventory levels a closely

watched market indicator.

Port Terminals

Deep-water ports require significant storage to buffer between tanker arrivals and refinery consumption. The Houston

Ship Channel region, Rotterdam in Europe, and Singapore serve as global storage hubs handling massive import/export

volumes.

Storage at ports allows cargoes to be accumulated for economic vessel sizes and provides receiving capacity

regardless of immediate refinery needs. Without this buffering, shipping logistics would be far more complex and

costly.

| Storage Location | Approximate Capacity | Primary Function |

|---|---|---|

| Cushing, Oklahoma | ~90 million barrels | Mid-continent hub, WTI pricing |

| Gulf Coast (Various) | ~300+ million barrels | Refinery supply, import/export |

| US Strategic Petroleum Reserve | ~372 million barrels (current) | Emergency government reserve |

| Rotterdam (Netherlands) | ~120 million barrels | European trading hub |

| Singapore | ~50+ million barrels | Asian trading hub |

How Storage Affects Prices

Storage inventory levels directly influence oil prices through fundamental supply and demand. When storage is

building (more oil entering than leaving), prices face downward pressure. When storage is drawing (more leaving than

entering), prices tend to rise.

The weekly U.S. inventory reports from the Energy Information Administration move markets significantly. A

larger-than-expected build suggests supply exceeds demand, pushing prices lower. A larger-than-expected draw

suggests demand exceeds supply, pushing prices higher.

The 2020 Storage Crisis

The spring 2020 COVID-19 demand collapse demonstrated what happens when storage approaches physical limits. As

lockdowns eliminated driving and flying, demand fell roughly 30%. Production continued, storage filled rapidly. When

Cushing approached capacity limits, the May 2020 WTI futures contract briefly traded at -$37 per barrel—sellers

paying buyers to take oil because there was nowhere to store it.

This extraordinary event illustrated storage’s crucial role. Without storage availability, even valuable commodities

become worthless because they have nowhere to go.

Tank Farm Operations

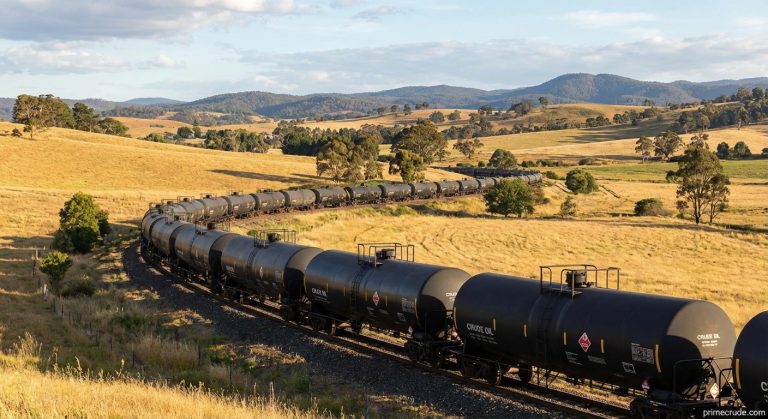

Tank farms consist of multiple storage tanks connected by pipelines to receiving and delivery infrastructure. Crude

oil terminals receive oil from pipelines or tankers, measure and quality-test incoming volumes, and store product

until customers request delivery.

Different crude grades typically require separate storage to maintain quality specifications. Light sweet crude,

heavy sour crude, and various intermediate grades each need dedicated tankage or careful segregation.

Tank Design and Safety

Large crude storage tanks are typically floating-roof designs where a steel roof floats directly on the oil surface,

eliminating vapor space that could accumulate flammable gases. Fixed-roof tanks are used for some products where

vapor recovery is practical.

Safety systems include containment berms surrounding tanks to capture leaks, fire suppression equipment, vapor

recovery systems, and continuous monitoring. Regulatory requirements from EPA and state agencies govern tank

construction and operation.

Terminal Ownership and Operations

Major terminal operators include Magellan Midstream, Enterprise Products Partners, Plains All American, and other

midstream companies. These operators build, own, and lease storage capacity to oil producers, refiners, and traders.

The business model involves charging customers per barrel per month for storage capacity, plus fees for moving oil

in and out. Revenue depends on storage utilization rates and the fees the market will support.

Contango and Storage Economics

When oil for future delivery costs more than immediate delivery—a market structure called “contango”—traders can

profit by buying oil now, storing it, and selling futures for later delivery. This contango trade drives storage

demand and utilization.

During strong contango periods, storage fills rapidly as traders pursue these profits. Storage rates rise to reflect

increased demand. When contango narrows or flips to “backwardation” (near-term prices higher than future), the trade

becomes unprofitable and storage demand falls.

The Strategic Petroleum Reserve

The U.S. Strategic Petroleum Reserve, created after the 1970s oil crises, maintains government-owned oil in salt

caverns along the Gulf Coast. Designed to hold up to 714 million barrels, current inventory stands around 372

million barrels following major releases in 2022.

The SPR provides emergency supply in case of major disruptions. Authorized releases have occurred following

hurricanes, geopolitical crises, and in 2022 to address high prices following Russia’s invasion of Ukraine.

SPR Debates

The appropriate size and use of the SPR generates ongoing debate. Critics argue the 2022 releases were politically

motivated price management rather than true emergency response. Supporters counter that high prices constitute an

economic emergency justifying release.

The depleted reserve level—now at a 40-year low—reduces buffer capacity for future emergencies. Refilling the SPR at

current prices would cost significantly more than the sales generated.

Global Storage Infrastructure

While U.S. storage is extensive, global trading depends on storage infrastructure worldwide. Singapore serves as the

Asian trading hub with significant tank capacity. Rotterdam handles European trading and benchmark pricing. Middle

Eastern producers maintain storage for export operations.

Floating storage—crude oil held in tankers at sea—supplements land-based capacity during dislocations. When land

storage fills, traders lease tankers for storage. This floating storage peaked at over 200 million barrels during

2020.

China’s Strategic Buildup

China has built substantial strategic petroleum reserves over the past two decades, reportedly holding over 500

million barrels. The opacity of Chinese inventory data creates market uncertainty—releases or fills can move markets

without clear advance indication.

This strategic stockpiling reduces China’s vulnerability to supply disruptions while also affecting global supply

and demand balances.

Market Transparency

Inventory tracking provides crucial market transparency. The U.S. Energy Information Administration reports weekly

crude and product inventories. Commercial data services estimate inventories in other countries using satellite

imagery, vessel tracking, and other methods.

These inventory reports move markets because they reveal actual supply and demand conditions. Persistent builds

indicate oversupply; persistent draws indicate undersupply. The direction and magnitude guide price expectations.

Limits of Transparency

Not all storage is tracked equally. U.S. commercial inventories are well-documented; other countries provide less

reliable data. Strategic reserve operations often occur without advance notice. Private company decisions about

storage optimization remain proprietary.

These information gaps create trading opportunities for those with better data and market risks for those without.

Future of Oil Storage

As energy transitions progress and oil demand eventually declines, storage infrastructure faces uncertain futures.

Tanks that took decades to build may become stranded assets if throughput falls below economically viable levels.

Some storage may repurpose for new uses—hydrogen, ammonia, biofuels. Other facilities may simply be decommissioned.

Planning for this transition while maintaining current reliability presents infrastructure challenges.

Near-Term Continued Importance

Regardless of long-term trends, storage remains essential for current oil market operations. Growing production in

key basins requires midstream infrastructure to reach markets. Trading and logistics optimization continues

demanding flexible storage.

Investment in storage capacity continues, though perhaps more cautiously than in previous decades given demand

uncertainty.

Conclusion

Crude oil storage terminals and tank farms, while invisible to most consumers, play crucial roles in determining

fuel prices. Their inventory levels signal supply and demand conditions, directly influencing market expectations.

When storage fills, prices collapse; when storage empties, prices spike.

The strategic importance of storage—both commercial operations and government reserves—shapes energy security

policy. The massive 2022 SPR release demonstrated how government storage can influence markets, though at the cost

of depleting emergency capacity.

Understanding storage helps interpret energy market dynamics. The weekly inventory numbers that move oil prices make

more sense when you understand the physical infrastructure—the tank farms near ports and pipelines that hold the

fuel buffering the world’s energy supply.

The steel tanks holding crude oil near ports and refineries represent a hidden but essential link between

global oil production and the prices consumers pay—buffers that make modern energy markets possible.