As nations work to decarbonize their energy systems, one of the most stubborn challenges is heating the hundreds of

millions of buildings that currently burn natural gas. Electric heat pumps offer one solution, but a growing chorus

of voices promotes a different path: replacing natural gas with hydrogen produced from renewable electricity. This

“green hydrogen” could theoretically flow through existing gas pipelines to home furnaces and boilers with minimal

modification. Is residential hydrogen heating practical, affordable, and coming soon? Or is it an expensive

distraction from more proven alternatives? The answer matters enormously for homeowners, utilities, and policymakers

planning energy transitions that will unfold over decades.

Understanding Green Hydrogen Basics

Hydrogen isn’t a fuel source in the traditional sense. Unlike natural gas or oil, which we extract from the ground,

hydrogen must be manufactured using energy from other sources. How you produce hydrogen determines its environmental

impact, with color-coded labels distinguishing different production methods.

Green hydrogen uses renewable electricity to split water molecules (H2O) through a process called electrolysis. The

hydrogen and oxygen separate; the hydrogen becomes fuel while the oxygen is simply released. Because the electricity

comes from wind, solar, or other renewables, and the only byproduct of water is oxygen, green hydrogen is

effectively carbon-free.

Other Hydrogen Colors

Gray hydrogen, currently the dominant form, comes from steam reforming natural gas. This process releases

substantial carbon dioxide. Blue hydrogen adds carbon capture to gray hydrogen production, reducing but not

eliminating emissions. Turquoise hydrogen uses methane pyrolysis to produce hydrogen and solid carbon. Each color

represents different cost and carbon tradeoffs.

For residential heating to deliver genuine climate benefits, the hydrogen used must be green or at minimum

low-carbon. Using gray hydrogen in home furnaces would actually increase emissions compared to burning natural gas

directly, defeating the purpose of the switch.

How Hydrogen Heating Would Work

In theory, hydrogen could replace natural gas in home heating with relatively modest changes. Hydrogen burns with a

hot, nearly invisible flame that can heat air or water in furnaces and boilers similar to current equipment. Some

existing gas infrastructure can handle hydrogen with modifications; purpose-built hydrogen equipment works even

better.

The basic concept involves producing hydrogen at large facilities using renewable electricity, transporting it

through pipeline networks, and burning it in home appliances. When hydrogen burns, it combines with oxygen to

produce water vapor and heat—no carbon dioxide, no carbon monoxide, no particulates that natural gas combustion

creates.

The Blending Approach

Rather than a complete switch, many utilities are testing hydrogen blends—adding hydrogen to natural gas streams at

5-20% by volume. This approach uses existing infrastructure and appliances with minimal modification. The blended

gas burns slightly differently but remains compatible with standard equipment.

Blending provides a transitional path that lets infrastructure and appliances evolve gradually. However, blending at

low percentages delivers only modest emissions reductions. A 20% hydrogen blend reduces carbon emissions by only

about 7% because hydrogen has lower energy density than natural gas. Substantial decarbonization requires much

higher hydrogen concentrations or complete conversion.

Infrastructure Challenges

Moving from pilot projects to widespread residential hydrogen heating requires massive infrastructure development

that doesn’t currently exist. The challenges span production, transmission, distribution, and end-use

equipment—essentially the entire energy value chain.

Production scale presents the most immediate obstacle. Current global green hydrogen production is measured in

thousands of tons annually. Heating a substantial fraction of homes currently using natural gas would require

millions of tons. Building the renewable electricity generation and electrolyzer capacity for this scale requires

trillions of dollars of investment over decades.

Pipeline Compatibility Questions

Existing natural gas pipelines pose uncertain compatibility with hydrogen. Steel pipes can suffer hydrogen

embrittlement, where hydrogen molecules penetrate the metal and cause cracking. Many modern pipelines use materials

that handle hydrogen better, but aging infrastructure may require replacement.

The distribution network—smaller pipes running under streets and into homes—faces similar questions. Older systems

often include materials that may not safely carry hydrogen. Upgrading this last-mile infrastructure represents an

enormous undertaking in densely built areas.

Storage Complexity

Storing hydrogen at scale proves more challenging than natural gas storage. Underground salt caverns can store

hydrogen, but fewer suitable sites exist compared to natural gas storage. The same volume of storage holds roughly

three times less energy when filled with hydrogen versus natural gas due to hydrogen’s lower volumetric energy

density.

Seasonal storage to handle winter heating demand peaks requires massive capacity. Whether sufficient geological

storage exists for a hydrogen heating economy remains uncertain and varies greatly by region.

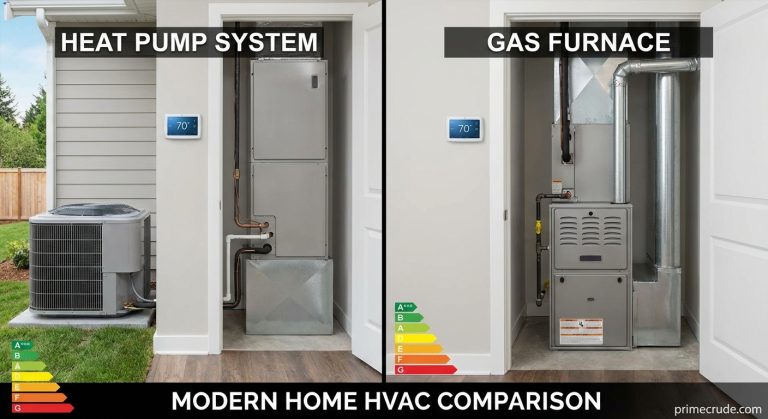

Efficiency Concerns: The Electric Alternative

The most fundamental challenge facing hydrogen heating isn’t infrastructure—it’s physics. Converting electricity to

hydrogen and back to heat loses energy at each step. Electric heat pumps, by contrast, use electricity to move heat

rather than create it, achieving efficiencies of 300-400%.

Consider a unit of renewable electricity. Used directly in a heat pump, it might deliver 3-4 units of heat energy

into a home. Used to make green hydrogen that’s then burned for heat, it might deliver only 0.5-0.6 units of heat.

The hydrogen pathway wastes 80-85% of the original renewable electricity.

The Renewable Electricity Constraint

This efficiency gap matters enormously because renewable electricity remains constrained. Every kilowatt-hour used

inefficiently for hydrogen heating is unavailable for more efficient uses. A world building limited renewable

capacity should prioritize applications where hydrogen offers unique advantages—heavy industry, shipping,

aviation—rather than heating where alternatives exist.

Advocates counter that renewable electricity will eventually become abundant and cheap enough that efficiency

matters less. They argue that some buildings are difficult to retrofit for heat pumps, and hydrogen offers a path

for those cases. The debate continues between those prioritizing theoretical flexibility and those emphasizing

near-term efficiency.

Real-World Pilot Projects

Despite challenges, hydrogen heating pilots are underway in several countries. The UK has been particularly active,

with projects in Scotland and Northern England testing hydrogen delivery and equipment in actual homes. These pilots

provide invaluable real-world data on performance, safety, and consumer acceptance.

The HyDeploy project demonstrated blending up to 20% hydrogen into natural gas networks serving several hundred

homes. Participants reported no noticeable difference in heating performance. Similar blending tests in France,

Germany, and Australia have shown comparable results.

The H21 Program

The UK’s H21 program envisions converting the city of Leeds to 100% hydrogen heating. Extensive engineering studies

have assessed the feasibility of converting the existing gas network and transitioning appliances. The program

represents the most detailed examination of full conversion anywhere in the world.

H21’s technical findings suggest conversion is possible but expensive. The economics depend heavily on future green

hydrogen costs and carbon pricing for alternatives. Whether the program proceeds to implementation remains a

political decision that balances cost, emissions reductions, and alternative pathways.

Appliance Considerations for Homeowners

Switching to hydrogen heating would require either modifying or replacing home furnaces, boilers, and other gas

appliances. The extent of modification depends on the hydrogen concentration and specific equipment involved.

Low-percentage blends (under 20%) generally work with existing appliances, though some manufacturers recommend

inspection and possible burner adjustment. Higher concentrations require more significant modifications or

purpose-built hydrogen appliances.

Hydrogen-Ready Boilers

Some boiler manufacturers now offer “hydrogen-ready” models designed to work with both natural gas and hydrogen.

These appliances need only minor modifications to switch fuels, protecting homeowners from having to buy entirely

new equipment when hydrogen becomes available.

Whether buying hydrogen-ready equipment today makes sense depends on local commitment to hydrogen heating. In

regions actively pursuing hydrogen conversion, the modest premium for compatible equipment may pay off. Where heat

pumps or continued natural gas use seem more likely, the premium may be wasted.

Safety Considerations

Hydrogen presents different safety characteristics than natural gas. It’s more flammable across a wider range of air

concentrations. It burns with a nearly invisible flame. It’s lighter than air and disperses quickly, which can be

advantageous.

Proper equipment design, installation, and ventilation manage these differences. Natural gas safety wasn’t inherent

either—it took decades of engineering to make gas appliances safe. Hydrogen appliances can achieve comparable safety

but require adherence to new standards and practices.

Cost Projections and Uncertainties

What would hydrogen heating cost homeowners? Estimates vary wildly depending on assumptions about green hydrogen

production costs, infrastructure investments, and carbon pricing of alternatives.

Current green hydrogen costs roughly $4-8 per kilogram, equivalent to natural gas at $30-60 per million BTUs—several

times current residential gas prices. These costs must fall dramatically for hydrogen to compete economically with

both continued natural gas use and heat pump alternatives.

Future Cost Trajectories

Industry projections suggest green hydrogen costs could fall to $1-2 per kilogram by 2040-2050 as electrolyzer costs

decline and renewable electricity becomes cheaper. At these levels, hydrogen heating might approach parity with

other low-carbon options, though it would still likely cost more than unabated natural gas.

However, these projections carry substantial uncertainty. Electrolyzer manufacturing must scale by orders of

magnitude. Supply chains for critical materials must develop. Renewable electricity must become abundant enough that

allocating it to hydrogen production makes sense.

Comparing Hydrogen to Alternative Futures

Evaluating hydrogen heating requires comparing it to realistic alternatives rather than judging it in isolation. The

main competitors are continued natural gas use (with or without carbon pricing), electric heat pumps, and district

heating from various sources.

Heat pumps currently offer the most efficient path to decarbonizing heating. Modern air-source heat pumps work well

in most climates and cost less to operate than resistance electric heating or hydrogen at current prices.

Ground-source heat pumps offer even better efficiency where installation is practical.

Where Hydrogen Might Win

Hydrogen heating might make sense in specific niches:

- Buildings extremely difficult to retrofit for heat pumps

- Regions with severe cold where heat pumps lose efficiency

- Areas with abundant cheap renewable electricity and hydrogen production capacity

- Industrial areas where hydrogen is produced for other purposes and excess is available

These niches might be important but probably don’t justify wholesale conversion of residential heating to hydrogen

where alternatives work well.

Policy and Utility Perspectives

Gas utilities facing potential obsolescence in electrification scenarios have championed hydrogen as a way to

preserve their infrastructure and business models. This self-interest doesn’t necessarily make hydrogen wrong, but

it suggests policy analysis should be independent of utility advocacy.

Some policymakers see hydrogen as offering consumer choice—letting households decide between electrification and

continued gas heating. Others worry that pursuing hydrogen distracts from faster, cheaper electrification pathways

and delays emissions reductions.

Regional Policy Approaches

The UK appears most committed to serious consideration of hydrogen heating. EU policy increasingly favors

electrification while reserving hydrogen for harder-to-decarbonize sectors. U.S. policy remains fragmented, with

some states pursuing building electrification and others supporting continued gas use with minimal hydrogen focus.

These policy differences will shape infrastructure investments over coming decades. Homeowners in different regions

face quite different likely futures for their heating systems.

Timeline for Residential Hydrogen

When might homeowners actually see hydrogen available for heating? Realistic timelines extend much further than

optimistic industry projections suggest.

Through the 2020s, activity will remain limited to pilot projects and low-percentage blending trials. Production,

infrastructure, and equipment simply can’t scale faster. Homeowners won’t face hydrogen-related decisions unless

they live in designated pilot areas.

The 2030s and Beyond

The 2030s might see expanded blending programs in regions with supportive policy and suitable infrastructure. Some

urban networks might attempt higher-concentration conversions. Still, this would affect limited geographies rather

than broad markets.

Widespread residential hydrogen heating, if it happens at all, is a 2040s or 2050s phenomenon. By then, the

technology and cost trajectory of heat pumps will have advanced further. Many buildings will have already

electrified. Hydrogen’s window as a residential heating fuel may close before it fully opens.

What Homeowners Should Do Today

Given the uncertainty about hydrogen heating’s future, what should homeowners considering heating system

replacements do now?

For most homeowners, waiting for hydrogen makes little sense. Heat pumps work well today, offer immediate operating

cost and emissions benefits, and don’t depend on infrastructure that doesn’t exist. Investing in heat pump

technology positions you for a low-carbon future regardless of what happens with hydrogen.

If You’re Sticking with Gas

If heat pump installation isn’t practical for your situation and you’re replacing a gas furnace or boiler, consider

hydrogen-ready equipment where available at modest premium. This preserves options without betting heavily on

hydrogen’s success.

Monitor local policy developments, as some regions may see faster hydrogen development than others. Stay skeptical

of utility claims that hydrogen is imminent—the infrastructure timeline is longer than marketing suggests.

Conclusion

Green hydrogen for home heating represents an intriguing possibility that faces substantial obstacles in cost,

infrastructure, and efficiency. While pilot projects demonstrate technical feasibility, the gap between small

demonstrations and economy-wide deployment remains enormous.

For most homes, electric heat pumps offer a more practical decarbonization path that’s available today rather than

decades hence. Hydrogen may find its role in industrial applications and heavy transport where electrification is

truly difficult, while residential heating follows the more efficient electrical pathway.

Homeowners should view hydrogen heating with interest but not yet reliance. The technology might develop faster than

skeptics expect, or it might remain a niche application. Making heating decisions today based on hydrogen

availability that may never materialize could prove costly.

The promise of green hydrogen heating remains real but distant. Most homeowners are better served by proven

alternatives available now rather than waiting for infrastructure that may take decades to arrive.